- NORKA Automation - Wir denken Licht neu!

- +49 4239 78530 0

- info@norka-automation.de

ScaleControl

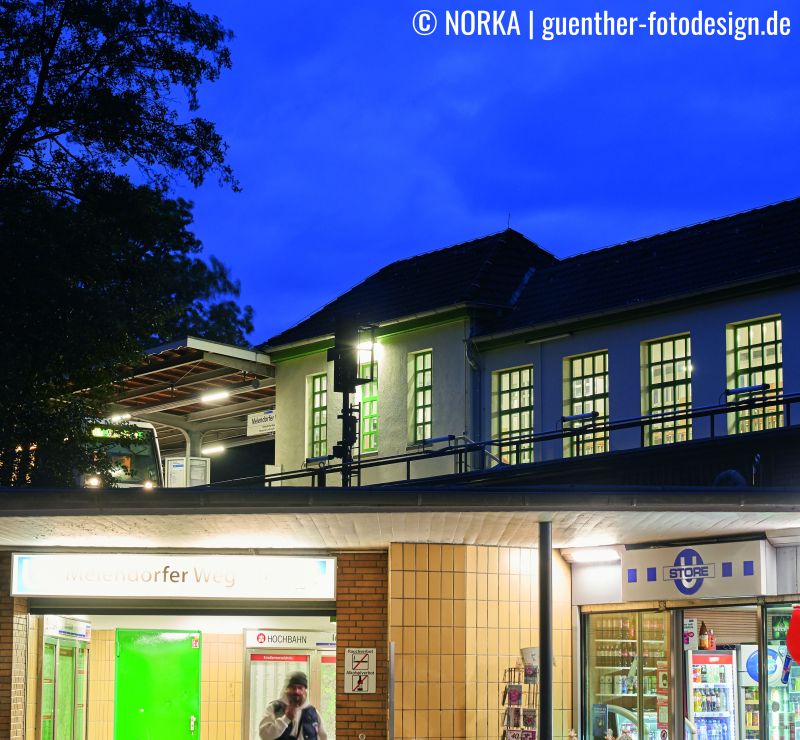

ScaleControl lighting management system on the railway station „Meiendorfer Weg“ in Hamburg

Forward-looking. Demand-oriented. Reliable. Secure.

With our reliable partner NORKA, we implemented our ScaleControl-solution as XARA® lighting management system at Hamburger Hochbahn in the year 2019. At the “Meiendorfer Weg” railway station, the final version of the control system was successfully put into operation in August 2019. For Hamburger Hochbahn, this is the first completely automatic lighting control system at a railway station.

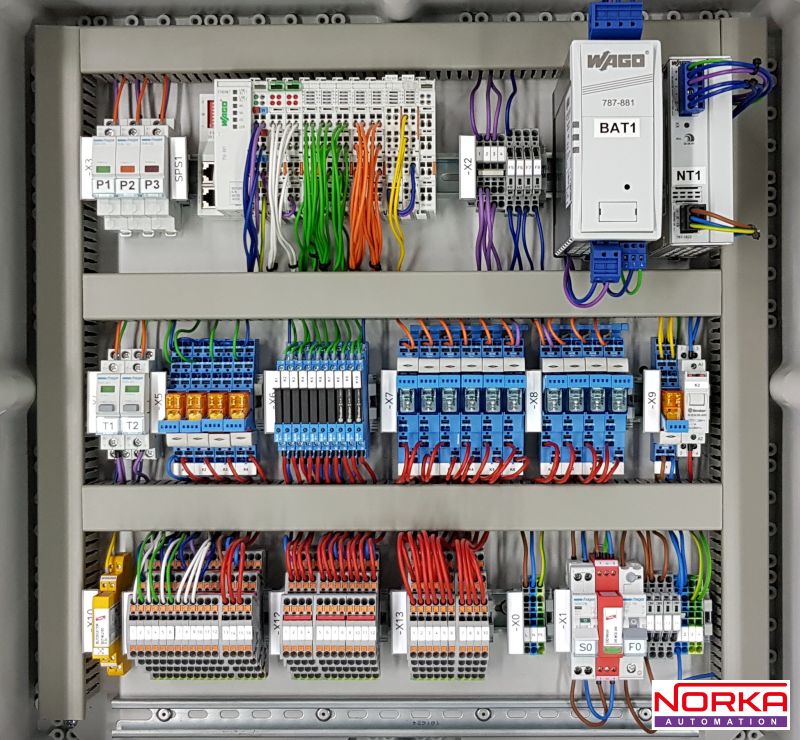

Control cabinet & software

The WAGO-based PLC control system with overvoltage protection, coupling relays and terminal points found a place in a compact 23.6 inch x 23.6 inch appliance class II housing in an IP65 design. The unit was planned, equipped and wired in our company. It was delivered to the customer ready for connection. Of course, we also included the corresponding wiring plan as well as the installation instructions.

The control software used was also developed in-house. It was tailored to the operational needs of a railway station and the wishes of Hamburger Hochbahn. The requirements for the control system of a station differ significantly from those of a industrial hall. On the one hand, this is due to the fact that maintenance staff only visit the stop sporadically, in the best case only in the event of a failure. On the other hand, the railway station is a public area with a lot of passenger traffic. Therefore, various behavioural scenarios of the control system must be programmed in advance for possible critical events.

Connection to the operations centre

The entire control system has a bidirectional connection to the operations centre of Hamburger Hochbahn. The lighting control system of the railway station is operated via remote signals from the control centre of the railway with a few signals. For example, it is possible to switch between the operating modes “operating break” or “normal operation”. In return, the control system reports its operating status back to the control centre. Furthermore, the control system is connected to the central emergency battery supply and has an additional internal UPS for the case of a power failure.

Normal operation & night light function

Several light and motion sensors are placed on the railway station, which feed the control system with additional signals. During the normal operation of the railway station, the following functions are active, such as daylight-dependent lighting control on the platform, daylight- and motion-dependent lighting control in the station hall as well as daylight-dependent switching of the information lighting, path lighting and the lighting for service areas.

The night-light function has been implemented for the “operating break”. The luminaires are switched to a possible minimum brightness. The illuminance on the ground corresponds to approx 5 lux. Thus, the railway station is minimally illuminated in all corners. This increases safety, prevents vandalism and at the same time reduces light pollution.

Error management

Independent of the operating modes, the lighting control system permanently monitors the DALI bus and the status of all DALI luminaires. If errors are detected, the controlling of the luminaires is changed, thus minimising the effect of the error. At the same time, errors are reported to the control centre, thus signalling a need for maintenance. The control system detects faults and provides information on the cause of the faults. With the help of this diagnosis, it has already been possible several times to locate leaking junction boxes within a very short time and to effectively eliminate faults.

Integrated safety lighting

Special treatment was given to the safety lighting. Visually and functionally, the safety luminaires are integrated into the general lighting. This integration brings a number of technical and aesthetic advantages. The loading of the safety lighting and thus also the ageing of the luminaires is the same as for the general lighting. In normal operation, safety luminaires have the same brightness as the rest of the lighting and promote a uniform lighting image of the railway station. In the event of malfunctions of these luminaires, the malfunction is immediately reported to the operations centre via a separate alert signal. In the event of a power failure, the safety lighting is switched over to battery operation and turned on to maximum light intensity. This guarantees the best illumination of the railway station in the event of an emergency.

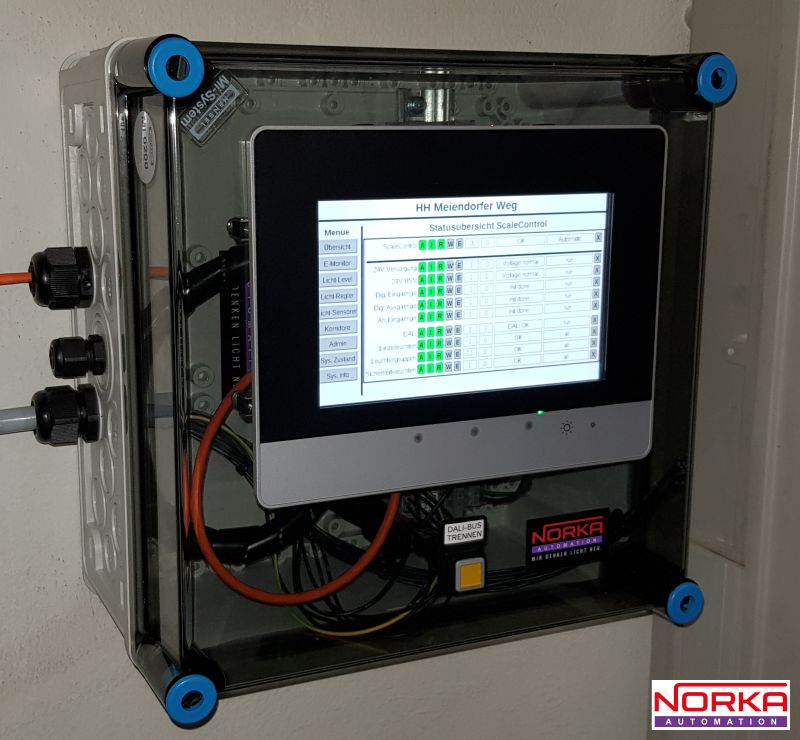

Touch panel, custom GUI & energy monitoring

A provided IP65 touch panel with an individual graphical user interface allows the service staff a differentiated error diagnosis of the lighting system on site. If necessary, this shows exactly which luminaire or sensor in the system have faults.

Integrated energy monitoring provides clear information on the energy consumption of all illuminated railway station areas. In addition, all control parameters can be re-parameterised in a password-protected GUI area.

Light compensation in case of luminaire failure

Another special function was implemented as part of this project. When a failure of one or more luminaires is detected, the luminaire failure light compensation function is activated in the affected area. For compensation, the dimming level of the neighbouring luminaires is raised around the failed luminaire. Thus, the required minimum illuminance is guaranteed in the affected area until the defective luminaire has been replaced or repaired.

With the fully automatic railway station lighting control system from NORKA Automation, railway customers can be provided with the best possible lighting comfort while at the same time ensuring maximum safety in every situation. For the operator, it offers a flexible, low-maintenance and reliable system that reduces energy consumption and minimises service costs.

- Extensive error management with implemented scenarios to catch errors

- Daylight control, twilight switch, motion-dependent light control

- Corridor functions

- Nightlight function

- Luminaire failure light compensation

- Energy monitoring

- Fault switching

- Self-diagnosis

- Touch panel with customised GUI

Picture sources: The correspondingly marked pictures were made available with the kind permission of the NORKA company. The picture rights to these images belong to Günther Fotodesign.